The wheel you need, at the moment you need it.

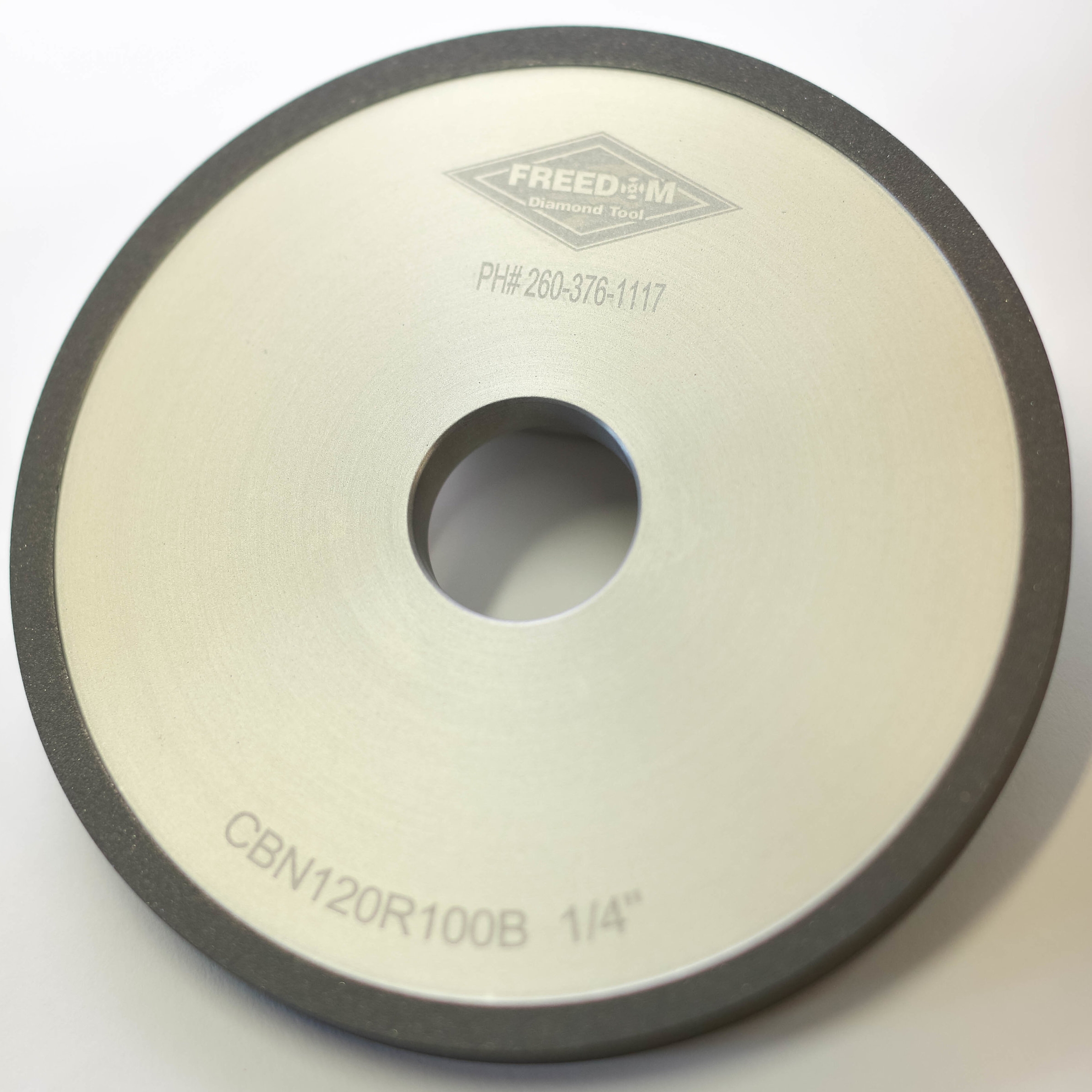

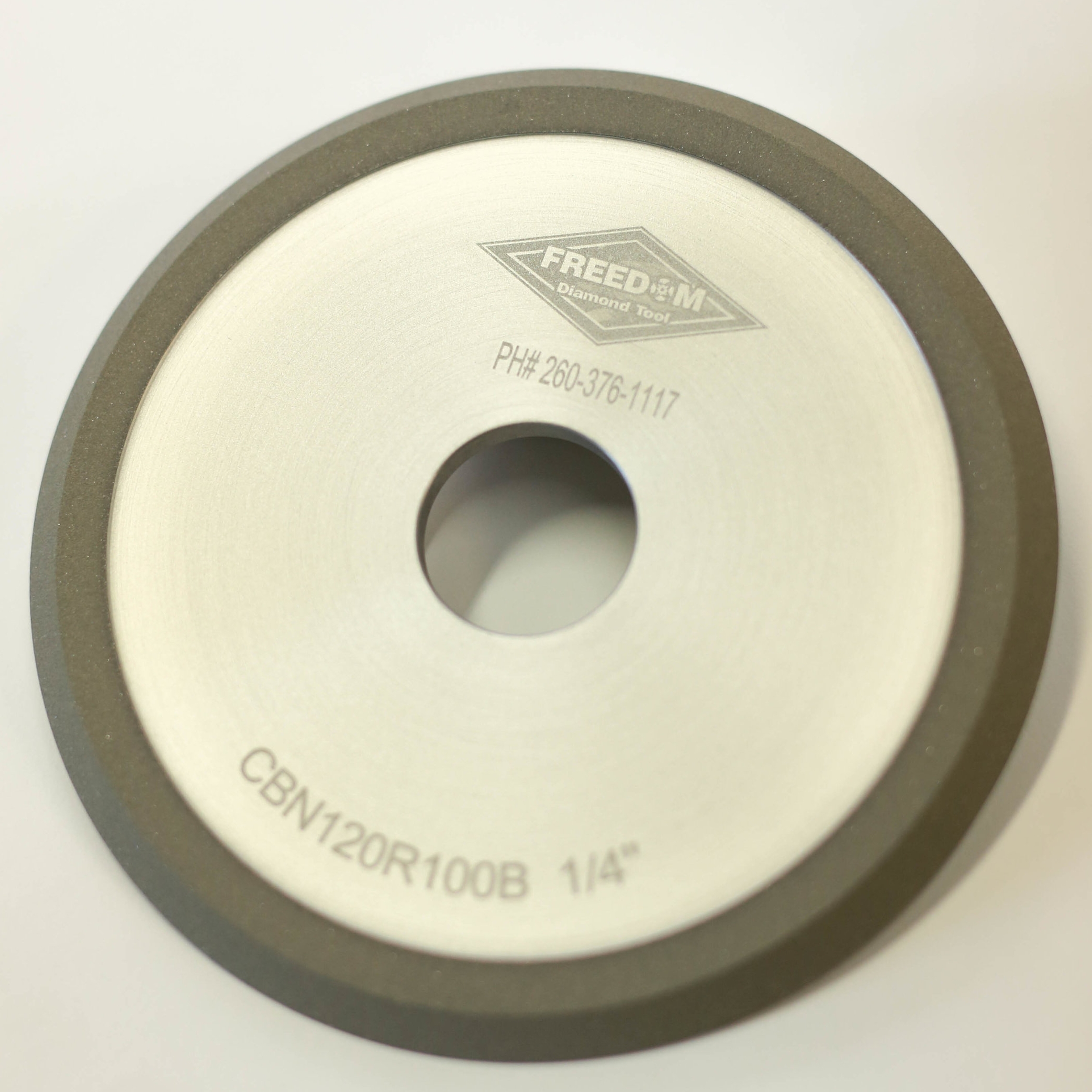

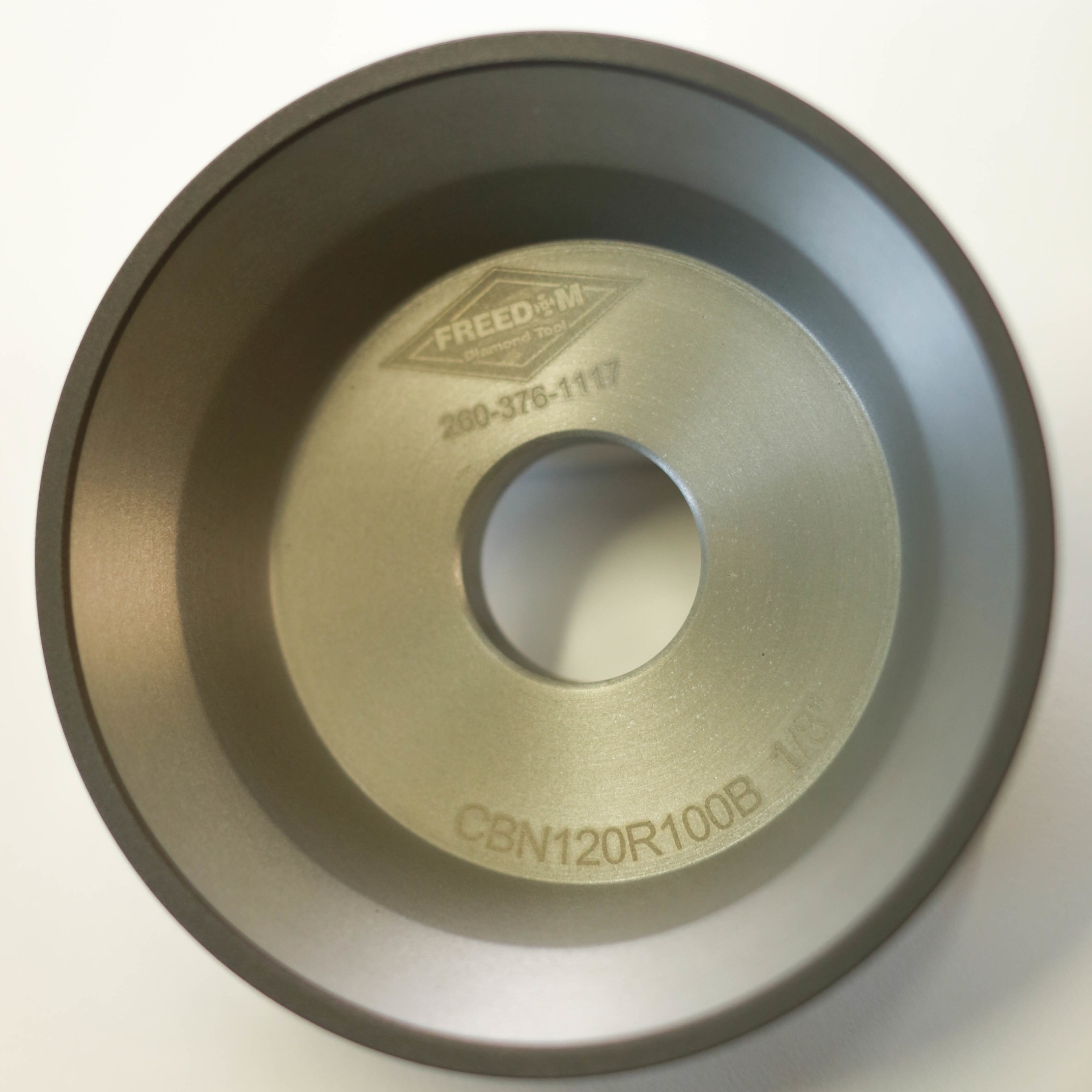

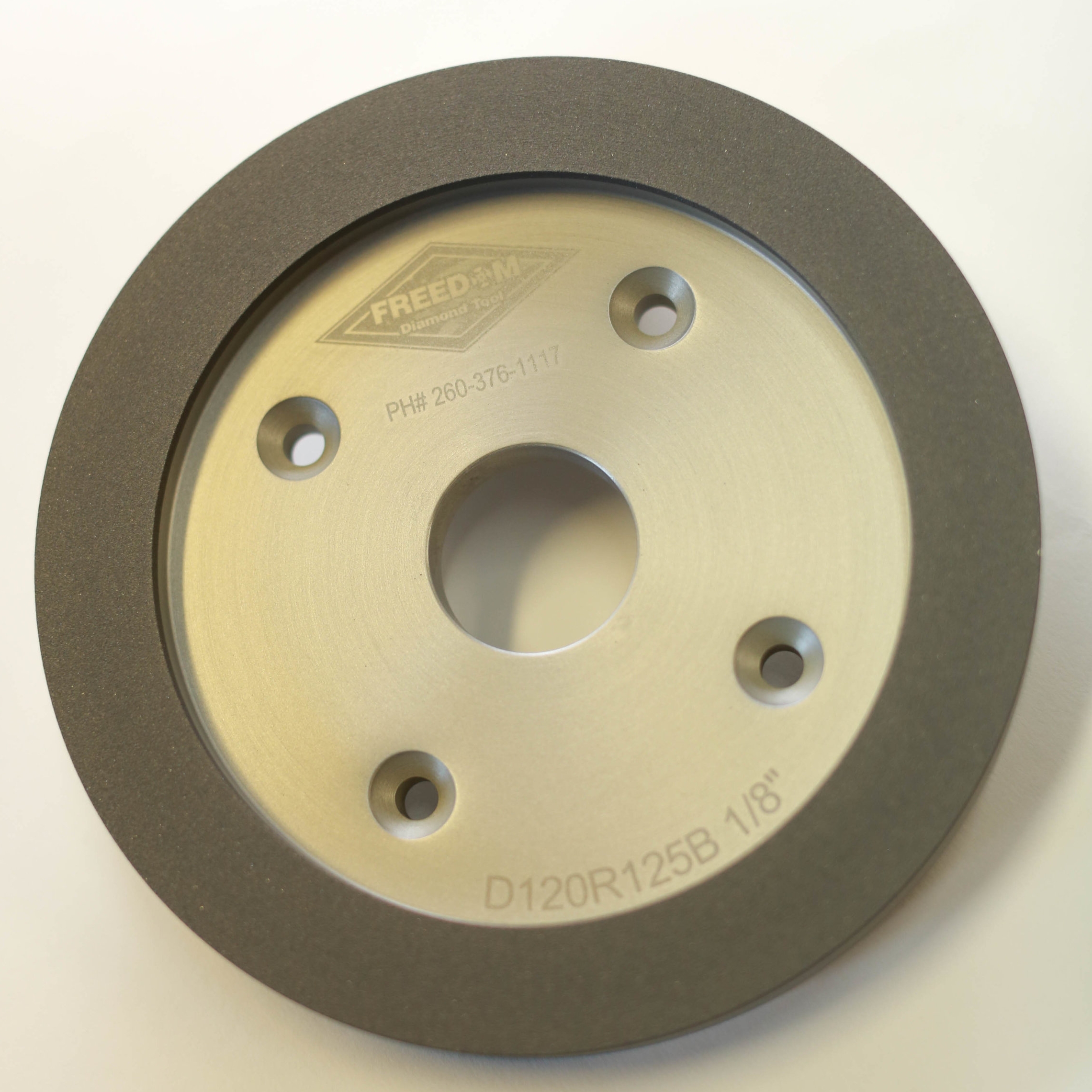

We produce only the highest quality hand-crafted products to exceed your expectations. Our Diamond Grinding Wheel Specialists create custom-manufactured diamond and CBN grinding wheels and tools with over 100 years of collective experience.